|

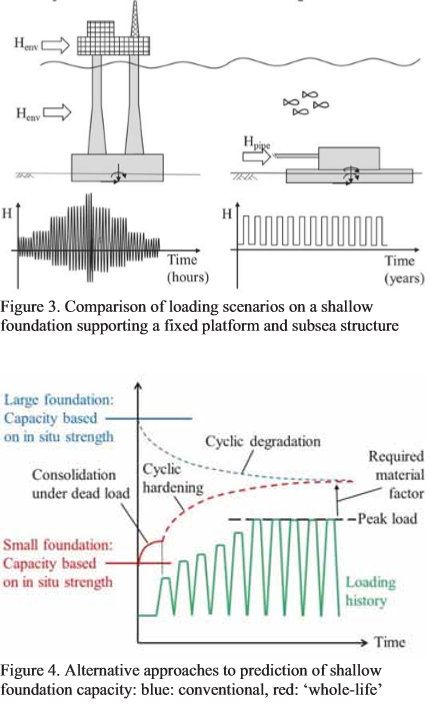

Recent papers from UWA/COFS have presented cutting edge developments in subsea foundation design which can allow significant optimisation of foundation sizes. This has direct practical benefits that have been seen in practise. As such, these papers have been of great use to the offshore industry and they are well summarised in this paper. Starting from the codified approaches of developing VHM interaction envelopes, how these have been improved upon to generate refined VHMT envelopes, how further gains can be made by accounting for consolidation from sustained vertical and lateral loading and then moving onto their work on sliding foundations. A similar publication was also made at OTC (OTC-27703) One of the critical aspects in subsea shallow foundation is the ability to assess them differently to fixed offshore installations which is typically the focal point of design codes). The figures below demonstrate the difference in typical loading regime and how this may impact the respective soil strength over time from foundation design perspective. In the final section of the paper a worked example of presented showing that for a particular PLET it may be possible to reduce the foundation size by 75% using the design methods provided, in the end moving from a fixed foundation with a structural sliding mechanism to accommodate pipeline expansion to a foundation which is designed to slide upon the seabed.

The following observations are made:

As such, the paper summarises some excellent research which allows industry to optimise the way that shallow foundations can be designed. However, the worked example that is provided does not best reflect how it can be used to optimise PLET foundation design.

0 Comments

Your comment will be posted after it is approved.

Leave a Reply. |

AuthorSGE. ArchivesCategories |

RSS Feed

RSS Feed